British Airways flight BA 38 accident and aviation fuel quantity aspects - part 6

British Airways flight BA 38 accident and aviation fuel quantity aspects - part 6

This is in continuation of “British Airways flight BA 38 accident and Aircraft Jet A-1 fuel System - part 5”, a blog series for understanding Aviation turbine fuel’s role in modern civil flights specially behaviour of water in fuel to mitigate it’s adverse effects during flight, including at high altitude where water will turn into ice. Last part gave a brief idea on fuel system, storage tanks, pumps, fuel feed manifold, fuel tank vents, fuel filters, fuel oil heater, fuel flow meter etcFrom fuel supplier’s perspective, it is interesting to know the aircraft systems which manage fuel quantity. This part gives idea on aviation fuel tanks, fuel quantity measurements and display to crew and related aspects on board thru B-777 British Airways BA 038 accident story.

The aircraft landed at Beijing at 0009

hrs on 17 January, 2008 from London with 4,100 kg in the right main, 4,000 kg

in the left main and 0 kg in the centre fuel tank. The temperature of the fuel in the left tank

was recorded as +10°C on departing Heathrow and -20°C on arrival at Beijing.

Sr. No.

|

Place, flight state, time

|

Jet A-1 Fuel Temperature

|

Remarks

|

1

|

Beijing, Flight arrival 0009 hrs on 17

January 2008, before refuelling, aircraft product,

|

-20°C

|

Arrival fuel Quantity

8100 kg from London

|

2

|

Beijing Aircraft refuel temperature. Flight departure

commenced 0155 hrs on 17 Jan 2008

|

5°C,

|

Jet A-1 Refuel quantity

71,401 kg

ambient temperature (-7°C)

|

3

|

At the time of Engine starting for take off. Aircraft took off at 0209

hrs

|

-2°C

|

28,900 kg in each of the main fuel tanks and 21,200 kg in the centre

fuel tank

|

Fuel Origin and Quality.

Aviation Fuel refuelled

was Jet A-1 originated from South Korea and was shipped to Tianjin, China and transferred

to the airport bulk fuel storage facility at Beijing. Fuel was certified to

meet Chinese

specification GB6537, issued by China’s National Technology Supervisory Bureau.

The GB6537 standard covers “No.3 Jet Fuel” which is basically equivalent to Jet

A1 and is the predominant kerosene type aviation fuel used in China.

Fuel quantity measurement on board

|

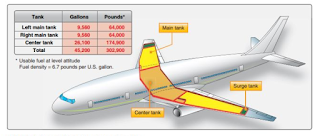

| Fig-1, B-777-200ER fuel tanks and capacities |

The fuel on the Boeing

777-200ER is stored in three fuel tanks: a centre tank, a left main tank and a

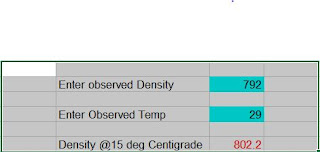

right main tank. A Fuel Quantity Processor

Unit (FQPU) receives signals from tank units and densitometers in the fuel

tanks and uses these to calculate the fuel quantity in the each of the three

fuel tanks.

The FQPU then sends data to

EICAS for the display of fuel quantity to the flight crew.(Fig-2)

Ultrasonic fuel Quantity Indicating System (FQIS)

|

| Fig-2. Fuel- Temp display in EICAS |

Each tank unit measures the fuel height at its

location, through the use of an ultrasonic transmitter /receiver. The FQPU commands each tank unit’s ultrasonic

transmitter to send out a sonic pulse, the time for the pulse to be

reflected from the fuel surface and return to the receiver directly relates to

the fuel height in the tank.

Each tank has measuring sticks

at various locations so that the fuel quantity can be manually checked on the

ground. The sticks use a magnetic float

which surrounds the measuring stick housing and rests on the fuel surface. Fuel quantity in the tank can then be

calculated using conversion tables, with reference to the aircraft’s pitch and

roll attitude, fuel density and the fuel heights measured at each of the stick

locations.

|

| Fig-3, Fuel Quantity Indicating System |

Water Detection

Ultrasonic sensors find

water in the bottom of a tank. The primary display system shows a maintenance

page message as an alert to the ground crew of water in a tank

Fuel Quantity Indication System (FQIS) water detection system. Three detectors, one in the centre fuel tank and one in each of the left and right main fuel tanks (indications recorded by the DFDR once every 64 seconds).

Flight Data Recorder (DFDR)

– Fuel Quantity recording (Fig 4)

|

| Fig-4, Flight data recorder (DFDR) |

In accordance with

regulatory requirements, the aircraft was equipped with a 25-hour duration and

a 120 minute Cockpit Voice Recorder (CVR).

Fuel Consumption in flight

Fuel consumption in any

flight is a function of many parameters like takeoff gross weight,

speed, cruise altitude, route of flight, temperature, wind in route etc. The accident flight BA-038 consumed total 68500

kg of fuel for 9.5 hour flying time carrying 152 passengers. For this flight this

translates into:

Fuel Consumed per hour = 7200 kg.

Fuel consumed per passenger = 450 kg

Fuel consumed per km flying = 8.45 kg.

For different aircraft fuel consumption related data can be read at Wikipedia Fuel economy in aircraft

Author's Profile

List of all blog articles on Petroleum QC by RJ Patel.

References:

-Report on the accident to Boeing 777-236ER, G-YMMM, at London Heathrow Airport on 17 January 2008

List of all blog articles on Petroleum QC by RJ Patel.

References:

-Report on the accident to Boeing 777-236ER, G-YMMM, at London Heathrow Airport on 17 January 2008

- Wikipedia https://en.wikipedia.org/wiki/British_Airways_Flight_38

-Boeing 777 refresher course GF 777

Chapter 14: Aircraft Fuel System - FAA

Earlier parts of this series:

British Airways flight BA 38 accident and Aircraft Jet A-1 fuel System - part 5

British Airways flight BA 38 accident and Jet A-1 fuel temperature - part 4

British Airways flight BA 038 flight altitude and Cold fuel Management - part 3”

British Airways flight BA 38 accident and Aircraft Jet A-1 fuel System - part 5

British Airways flight BA 38 accident and Jet A-1 fuel temperature - part 4

British Airways flight BA 038 flight altitude and Cold fuel Management - part 3”

Comments