- Myth of density variation 3.0 kg/m3 in Petroleum Industry , (a Scholarly article)

- Myth of density variation 3.0 kg/m3 in Petroleum Industry

Globally Oil industry Quality Manuals specify certain tolerance density variation for petroleum products like Gasoline, Diesel fuels, Aviation fuels etc, between density of dispatched products and density of received product. As long as this density difference remains less than permitted variation, the product is accepted in the system.Particularly in field operations and market have notion that as long as density variation of petroleum products remains less than +/- 3.0 kg/m3 compared to parent density, quality of product is OK ie. product meets specification requirements.

The above may be grossly wrong and consequence of practice of such error may result into a great loss financially as well as fetal if Kerosene contamination with highly volatile fuel like gasoline or Naphtha.

Let us study following examples of product blend prepared and tested for key parameters.

Table 1 - Density variation is 2.0 kg/m3 however, 2 % HSD in MS fails in Distillation Final Boiling Point ( limit for MS FBP is 210 C max) and Residue on Evaporation tests ( Limit 5 units).

Table 1.

Product

|

Density at 15C, Kg/m3

|

FBP

Deg C

|

ROE

|

MS (Gasoline)

|

734

|

192

|

1

|

HSD (Gasoil)

|

832

|

372

|

-

|

2% HSD

in MS

|

736

|

232

|

758

|

Table 2 below - Density variation is 2.0 kg/m3 however, 2 % MS in HSD fails in Flash Point for HSD, though Sulphur content remain with Specification limit of 50 ppm.

Table 2.

Product

|

Density

at 15C

|

Total Sulphur ppm

|

Flash

Point C

|

MS

|

734

|

24

|

--

|

HSD

|

832

|

45

|

42

|

2% MS

in HSD

|

830

|

42

|

28

|

Table 3 below - Density variation is 2.0 however, 3 % MS in kerosene fails in Flash Point for Kerosene, though Sulphur content remain with Specification limit of 50 ppm. Using Such kerosene of 5 deg C flash Point against specification limit of min 35 deg C is highly dangerous when used in stoves, causing fires resulting into fetal injuries.

Table 3.

Product

|

Density

at 15C

|

Total Sulphur ppm

|

Flash

Point C

|

MS

|

734

|

24

|

--

|

Kerosene

|

800

|

360

|

41

|

3% MS

in Kerosene

|

798

|

345

|

22

|

Table 4 below - Density variation is 4.0 however, 4 % Kerosene in MS does not fail in Distillation FBP and ROE tests.

Table 4.

Product

|

Density at 15C, Kg/m3

|

FBP

Deg C

|

ROE

|

MS (Gasoline)

|

734

|

173

|

1

|

SKO (Kerosene)

|

802

|

256

|

-

|

4% SKO

in MS

|

738

|

204

|

3

|

From above tables it is clear that

1. Density difference is less than 3 kg/m3 still product fails in table 1, 2 and 3

2. Density difference is more than 3 kg/m3 still product passes in table 4.

Lessons can be learnt:

1. Density variation of less than 3 kg/m3 usually means product pass specification, if there is no or very little contamination. Further detail lab testing can confirm.

2. Density variation more than 3 kg/m3 usually means the product quality is suspected, and may pass or fail specification. Further detail lab testing can confirm.

3. Since density of petroleum product is only means available in field, it helps if along with density difference, other parameters like sample appearance, visual colour etc also critically looked into to get indications of suspected contamination.

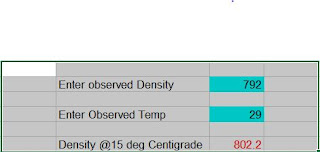

4. For comparing densities, it is must that in the field, observed densities are converted to 15 deg C first. Many a times, density conversion not done in the field due to ASTM conversion tables are not handy in field. ( Note - One can find easy way of converting density to 15 deg C without ASTM tables in the field - in this blog)

Hope, above brings clarity in prevailing Myth of density variation number 3.0 kg/m3 petroleum products.

Keywords : Hydrocarbon blends, Gasoline, Gasoil, Kerosene, ASTM Density

Author's Profile

List of all blog articles on Petroleum QC by RJ Patel.

Follow me on twitter @RJPatel13 to get notification when my new post is available in my blog.

Author's Profile

List of all blog articles on Petroleum QC by RJ Patel.

*******************************************************************************

Comments