- Relationship between Flash Point and Front-end Distillation data of petroleum products, (a Scholarly article)

- Relationship between Flash Point and Front-end Distillation data of petroleum products,

The relationship between Flash Point and Atmospheric front-end Distillation data of petroleum products, normally recorded during the routine testing are correlated during 1986 – 1988 period by a team (S/S RJ Patel, PD Dusane, NS Kamble, SK Shukla at IOC Kandla Laboratory ). The idea was originated from similar literature that time, W.L. Nelson ( Petroleum Engineering, pg 131, edition 1982, initially put forward in year 1944).

Team under the leadership of the author of this blog could

work out a most improved/accurate empirical relationship as given below:

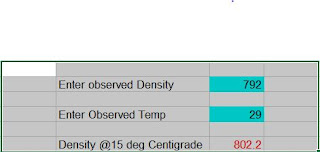

Predicted Abel Flash Point FP = 0.613*IBP + 0.193*T10 - 84.0.

( all temperatures

in deg Centigrade, C ).

Where, FP = Abel Flash Point deg, C

IBP= Initial Boiling Point as per ASTM D86 Distillation &

T10 = ASTM D86 Distillation, 10% recovery temperature

Where, FP = Abel Flash Point deg, C

IBP= Initial Boiling Point as per ASTM D86 Distillation &

T10 = ASTM D86 Distillation, 10% recovery temperature

The empirical formula has been derived by testing and

further revalidated more than 5000 Kerosene, Aviation Turbine fuel, and similar samples from products received at Kandla, which were derived

from a wide range of crudes and refineries from Russia, US, Venezuela,

China, Gulf countries, Singapore etc beside India. The team was benefitted

incidentally since India was importing finished products from a wide

global sources during the period mentioned.

Later on, some other work on the same subject appeared and

one such very reputed reference is found in API correlation (1997 version).

FP = 0.68*T_10%_D86 - 109.6 where FP: flash point

, ºF, T_10%_D86 : ASTM D86 10% temperature , ºF. Also, by D.S.J. Jones

(Elements of Petroleum Processing-Wiley) is: Flash

point = 0.77(ASTM 5% in oF - 150oF).

However, the author claims that the IndianOil Kandla

Laboratory team work is more accurate than the other existing known correlation

equations, though work done much earlier then, with following features:

It is most accurate, 2 parameters ( IBP and 10%T )

have been correlated rather than one. Flash Point of the sample can

be predicted accurately from routine Distillation data. When Distillation data

are very accurate, the flash point worked out is within precision of the test

methods. Also from Flash point, prediction of either IBP or T10 can be made

accurately. This was used extensively for verifying data in many round

robin programmes conducted by IndianOil Laboratories.

Performance of equipment/technicians, indirectly verifying

accuracy of thermometers, test protocol followed by technician etc is possible.

A caution is not out of place that any contaminated samples with volatile

products like gasoline will have error like result.

Author acknowledges other team members for their

contribution for the efforts towards deriving most accurate relationship

equation between Flash point and front end routine distillation data.

Hope the Petroleum technical community will be benefited by use of the

equation.

References :

Key Words : Flash Point Abel, Distillation D-86,

Follow me on twitter @RJPatel13 to get notification when my new post is available in my blog.

****************************************************************************

Comments