Difference between Colourless and Straw yellow Jet A-1 properties

Difference between Colourless and Straw yellow Jet A-1 properties

As given in last blog article normally colour of Jet A-1 is either colourless, straw/yellow or a very little shade of blue, pink or red. Reason for each colour was explained in the article.

Colour of Aviation turbine fuel depends upon a) composition of crude oil & 2) Refinery processes used in refining the crude. (Read in detail How the Aviation turbine fuel colour is colourless or straw/Yellow? ).

In this article we deal with differences between Colourless and straw yellow coloured fuel properties.

1. Straight Run product

Straight run product is referred as Jet A-1 obtained straight from Atmospheric distillation unit in refinery or derived from natural Gases condensate liquids.

Such Jet A-1 consist of natural original hydrocarbons of crude oil or natural Gases condensate liquids as existing in the earth and separated from it by only physical processes. Since no chemical reactions involved in this, the hydrocarbons are most stable.

Colour of such hydrocarbon depends upon the original colour of hydrocarbons from the earth. If the source contains some coloured Nitrogen/Sulphur compounds then Jet A-1 will also have this straw yellow colour. Otherwise, if absence the colour will be towards colourless.

The above para explain clearly that such Jet A-1 does not need anti-oxidant and Lubricity improver additives (LIA). The product is very good towards elastomers of fuel handling systems in field as well as aircraft- increasing elastomer life and thus protecting from fuel leak from material failure ( O-ring, gaskets etc).

The disadvantage seems - appearance due to pale yellow/straw colour is disliked as customers/operators think of fuel contamination erroneously. More education by Quality Assurance group is desired in such situation. Further in very long storage, such fuel will become more darker in yellow colour due to natural oxidation, however, this does not affect the fuel properties and its performance adversely.

List of all blog articles on Petroleum QC by RJ Patel.

2 Hydroprocessed Jet A-1

Usually to increase the Jet A-1 yield to meet the product demand, besides Atmospheric distillation, other secondary refining processes like hydroprossesing /hydrotreating/hydrofinishing of suitable streams from Vacuum distillation unit etc are involved in JEt A-1 production. As explained in last article, many chemical changes occur in such refining processes, including colour which will be colourless.

The colourless product, if hydro-treatment done properly, will remain colourless for very very long period. The author once kept one hydroprocessed batch Jet A-1 and evaluated Colour and key properties like colour, Existing Gum, distillation, PONA etc and found that the colour remain unaffected even after 5 years.

Also, it is seen, if hydro processing not done properly ie. if hydrogen quantity used is less or hydrogen quality is not as desired, Jet A-1 produced is unstable towards many properties like Colour, storage stability etc. This is more true , if the refiner has used unusually some cracked products from FCC etc to increase availability of more quantity of product to market.

Since hydroprocessing removes Nitrogen and Sulphur compounds greatly, the product obtained lacks the good properties listed and therefore need of adequate dose of additives ( anti-oxidants, LIA etc) are necessary to achieve the performance properties.

Further, manufacturing of hydroprocessed Jet A-1 is much more expensive than ADU straight run product as running product thru secondary units, time taken, costly hydrogen and catalysts used. Cost further increase due to mandatory additive requirement to enhance fuel performance.

Key Words:

Colourless Jet A-1, Hydro-treatment, Hydro-processing, ADU, FCC, LIA, anti-oxidants, Existent Gum.

Visit to my blog https://rjpatelioc-petroleum.blogspot.com for similar other work related to Petroleum Product QC. Some of following links may be useful:

List of all articles on Petroleum QC upto 06 Apr 2019 by author.

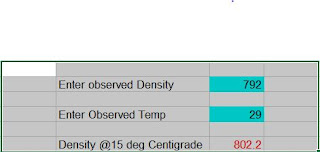

-Temperature around 3 deg C, - Density Conversion from observed temperature to 15 C without use of ASTM Table

Comments